Sunlightweld Exothermic Weld: Revolutionizing the Industry with Superior Technology and Cost Efficiency

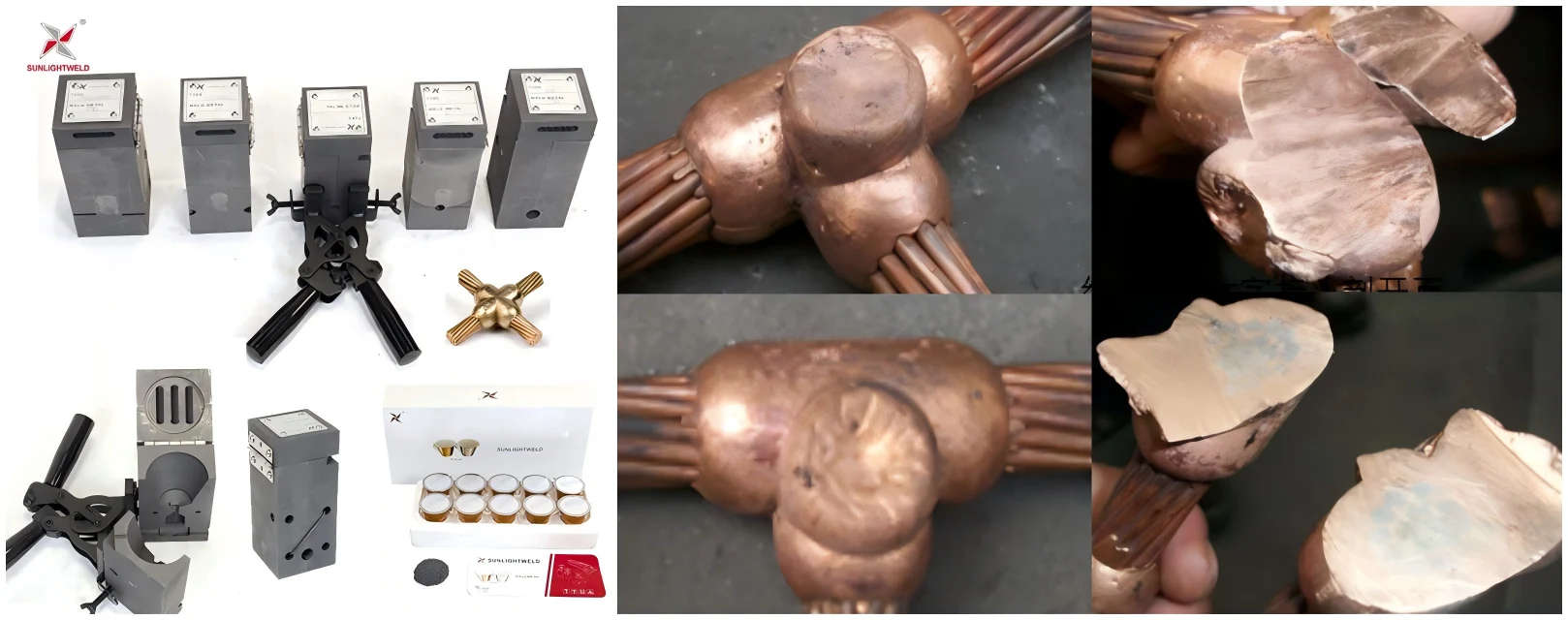

Exothermic weld, also known as thermite welding, is a popular and highly efficient method used to create permanent connections between conductors. This process generates heat by initiating a chemical reaction, which allows the welding material to flow into the joint, creating a strong, long-lasting bond. Among the various players in this field, Sunlightweld has emerged as a frontrunner by offering innovative, highly efficient, and cost-effective exothermic weld products. Sunlightweld electronic ignition exothermic weld is a revolutionary product that is equipped with advanced features and certifications to meet global standards.

Sunlightweld Exothermic Weld Certifications

One of the most significant selling points of Sunlightweld exothermic weld is its adherence to international quality and safety standards. The Sunlightweld exothermic weld holds various prestigious certifications, including IEEE837, UL467, IEC62561-1, CE, and RoHS certifications. These accreditations ensure that the product complies with strict safety and quality regulations, making it suitable for use in diverse industries, from power generation to electrical installations.

IEEE 837 Certification

IEEE 837 is an international standard that focuses on the reliability and durability of electrical connections, particularly for grounding systems in electrical power installations. By achieving IEEE 837 certification, SunlightWeld ensures that its exothermic weld delivers reliable and durable connections capable of withstanding harsh environmental conditions and high electrical loads, which is especially important for grounding applications.

UL 467 Certification

UL 467 is a safety certification for grounding and bonding equipment, ensuring that the product meets electrical safety standards in North America. Obtaining UL 467 certification means that Sunlightweld exothermic weld products meet the highest safety standards required in North America for electrical grounding equipment, guaranteeing long-term performance in critical installations.

IEC 62561-1 Certification

IEC 62561-1 is a standard issued by the International Electrotechnical Commission (IEC) for components used in lightning protection systems.This certification assures customers that Sunlightweld's products can provide effective and secure connections in lightning protection systems, ensuring that the connections will function safely even in lightning-strike environments.

CE Certification

The CE mark is a mandatory conformity mark for products sold in the European Economic Area (EEA), indicating that the product meets EU safety, health, and environmental protection standards.The CE certification allows Sunlightweld's products to be freely marketed and used in Europe, ensuring that they comply with rigorous European Union regulations for safety and performance.

RoHS Compliance

RoHS (Restriction of Hazardous Substances) is a European Union directive that limits the use of specific hazardous materials in electrical and electronic products. Sunlightweld's compliance with RoHS standards ensures that its exothermic weld does not contain harmful substances such as lead, mercury, or cadmium, making it environmentally friendly and safe for both operators and the environment.

In addition to these certifications, SunlightWeld has filed patents for its innovative exothermic weld technology in the United States, showcasing its commitment to leading-edge development and technology. This patent protects the company's core technology, including the ignition starter module design and the high-efficiency welding process, further solidifying its position as an industry innovator.

Key Advantages of Sunlightweld Exothermic Weld

1. 100% Ignition Rate

Sunlightweld electronic ignition exothermic weld boasts an impressive 100% ignition rate. The system utilizes a flexible design for the ignition starter module, ensuring it is less likely to shift or malfunction during use. This innovation guarantees consistent and stable ignition efficiency every time. Users can rely on Sunlightweld to ensure that the welding process will be initiated smoothly, without concerns of failed connections or interrupted operations.

2. Cost-Effectiveness: Faster and More Efficient Operations

One of the most appealing benefits of Sunlightweld electronic ignition exothermic weld is its reduced operational time. The entire exothermic weld process takes only a few seconds. By simply placing the E-plus exothermic weld cup into the graphite mold, attaching the ignition wire to the weld cup, and pressing a button to start, operators can begin the welding process almost immediately. This streamlined approach eliminates the need for time-consuming steps such as unsealing, adding steel sheets, sprinkling ignition powder, or manually initiating ignition. As a result, this efficiency saves up to 70% of operation time, significantly reducing the need for manual labor and offering a substantial cost-saving opportunity for businesses. This streamlined process not only speeds up production but also reduces the total operational costs, making it a highly cost-effective solution for companies involved in large-scale installations or projects.

3. Competitive Pricing and High Profit Margins

Sunlightweld's pricing structure is highly competitive, largely due to China's robust industrial system and lower labor costs. This allows Sunlightweld to offer more attractive prices than its competitors, enabling international distributors and partners to earn at least 30% more profit on the same products. With an emphasis on providing continual support, Sunlightweld helps its partners grow by offering training, technical support, and marketing assistance. To ensure the success of its global distribution network, Sunlightweld even provides virtual factory tours for potential partners to explore its manufacturing capabilities in China. By fostering a transparent and supportive relationship with its partners, Sunlightweld ensures the long-term success of their business ventures.

4. Enhanced Safety Features

Safety is always a top priority, especially when dealing with high-temperature processes like exothermic welding. Sunlightweld electronic ignition exothermic weld is designed with several safety features to protect operators. The ignition starter comes with a 1.8-meter power cord (with an optional 3-meter extension) and features a dual-switch design, reducing the risk of accidental activation. Additionally, the system includes a built-in warning function to alert operators of potential hazards, reducing the likelihood of accidents during the exothermic welding process. The ability to perform the welding from a distance further minimizes the risk of burns or injuries caused by direct exposure to the exothermic reaction. This focus on safety makes Sunlightweld a reliable and secure choice for industrial use.

5. Minimal Residue and Eco-Friendly Design

Sunlightweld takes environmental concerns seriously. One of the standout features of the E-plus cup used in the exothermic welding process is its involvement in the welding reaction itself. The entire copper cup participates in the exothermic reaction, blending seamlessly with the welding material. As a result, there are almost no residues left after the welding process, making the entire operation cleaner and more environmentally friendly.

By reducing waste and using eco-friendly materials, Sunlightweld ensures that its exothermic weld system is aligned with global sustainability efforts while also improving the efficiency of the welding process.

6. Safe and Efficient Transportation and Storage

Transporting and storing welding equipment often comes with challenges, particularly when it involves hazardous or fragile components. Sunlightweld electronic ignition exothermic weld, however, is designed with safety and efficiency in mind. The product contains no flammable or explosive elements, making it easy to transport via air without the need for special permits or precautions.

The packaging of Sunlightweld products also ensures that the system remains in pristine condition during transit. The eight-layer protective packaging, which is designed to be moisture and shock-resistant, guarantees that the product remains stable and functional even in less-than-ideal environmental conditions. This makes Sunlightweld products not only safer to transport but also easier to store and maintain for long-term use.

7. Comfortable and User-Friendly Operation

Sunlightweld electronic ignition exothermic weld is designed with ease of use in mind. The system is safe and intuitive, requiring minimal training and protective measures to operate. The dual-switch design minimizes the risk of accidental activation, and the system can be started within three seconds without producing black smoke, unpleasant odors, or harmful fumes. This makes the welding process not only safer for the operator but also more comfortable and environmentally friendly.

Moreover, Sunlightweld's ignition starter can operate in temperatures as low as -10°C, while many competitor models can only function in temperatures above 0°C. This extended temperature range makes Sunlightweld's exothermic weld system more versatile and reliable in a wider range of operating conditions.

Global Leadership Through Manufacturing Excellence and Collaboration

Sunlightweld's success is driven by China's robust manufacturing infrastructure, which enables the company to produce high-quality products at competitive prices. Leveraging China's efficient supply chain and established industrial ecosystem, Sunlightweld ensures fast production, stringent quality control, and cost-effective solutions, passing on significant savings to customers. This manufacturing advantage, combined with the company's commitment to innovation, positions Sunlightweld as a global leader in the exothermic welding industry. As the company expands, it actively seeks international partners and distributors, offering them exclusive access to its products along with training, technical support, and marketing assistance to foster mutual growth and success worldwide.

Sunlightweld exothermic weld represents the next generation of welding technology, combining high performance, safety, efficiency, and environmental responsibility in one compact solution. The company's commitment to quality, safety, and innovation, backed by its certifications and patents, makes Sunlightweld a leader in the global exothermic weld market. With the added benefit of competitive pricing, enhanced safety features, and minimal environmental impact, Sunlightweld is well-positioned to revolutionize the industry and continue to support its global network of partners in achieving greater success. As Sunlightweld expands globally, it remains dedicated to providing industry-leading products that help its partners maximize profitability while maintaining the highest standards of quality and safety.

https://www.sltup.com/Exothermic-Welding

https://www.sltup.com/Electronic-Ignition-Exothermic-Welding.html

www.sltup.com

Sunlightweld