Optimizing Elevator Efficiency and Safety with Barite Elevator Tension Devices

In modern architecture, elevators are indispensable for vertical transportation. They enhance accessibility and mobility within buildings, ensuring that occupants can efficiently move between different floors. An often overlooked but critical component of elevator systems is the tensioning mechanism, which ensures that the elevator operates smoothly and safely. Among the various types of tensioning devices, the barite elevator tension device stands out due to its unique properties and pivotal role in the functioning of traction elevators. This article Xizi Forvorda delves into the design considerations of barite elevator tension devices in elevator performance.

What is a Barite Elevator Tension Device?

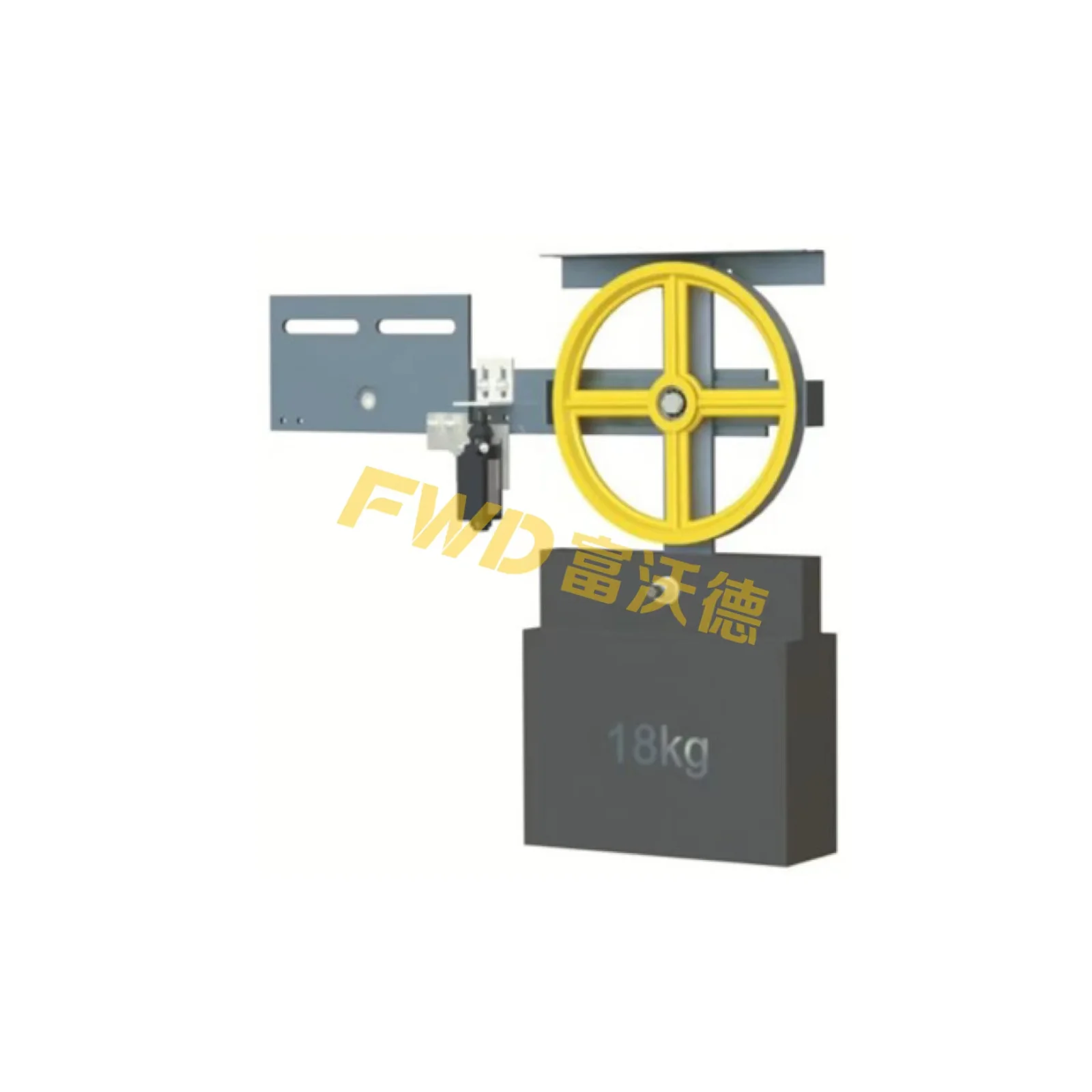

A barite elevator tension device is a crucial part of the traction system in elevators. Traction elevators, as opposed to hydraulic elevators, rely on cables or ropes that loop around a sheave and support the elevator car and counterweight. These ropes must maintain the proper tension to ensure smooth operation. The barite elevator tension device helps regulate the force exerted on these cables, keeping them within the ideal tension range.

Barite, a naturally dense mineral, is used in the design of these tensioning devices because of its superior weight and stability under stress. This unique material ensures that the tensioning system is highly effective and resistant to wear, even under extreme conditions. In addition to its physical properties, barite's ability to resist corrosion and its minimal expansion under temperature fluctuations make it an ideal material for use in tensioning devices that will be exposed to varying environmental conditions, contributing to a more robust and reliable elevator system.

The barite elevator tension device typically incorporates components such as rollers, adjustable springs, and guide pulleys that help maintain the tension in the ropes. By absorbing fluctuations in force, it ensures that the system remains stable and efficient regardless of the elevator's load, speed, or frequency of use. This mechanism is especially essential for elevators in large buildings or high-rise complexes, where elevators experience constant use and significant weight changes.

Design Considerations of Barite Elevator Tension Devices

Several factors influence the design and efficiency of a barite elevator tension device. These considerations are essential to ensuring that the device performs reliably and efficiently under all operating conditions. The following are some of the key design features and considerations:

1. Weight and Density of Barite

The primary reason barite is used in these tension devices is its high density. Barite is among the heaviest minerals, which gives the tensioning system the necessary weight to maintain steady tension in the ropes. This weight is essential because it helps ensure that the tensioning system remains stable, even in high-demand elevator systems. The density of barite also contributes to the device's ability to handle fluctuating loads, absorbing shocks and distributing forces evenly across the elevator system. The high density of barite also enhances the device's stability. As an elevator moves, external forces such as vibration, changes in load, or even the elevator's speed can cause variations in cable tension. Barite's weight helps dampen these variations, ensuring the cables remain taut without significant fluctuation, even under heavy or irregular loads.

2. Adjustable Tension Mechanisms

A key aspect of the barite elevator tension device is its ability to adjust the tension based on load variations. The device is often designed with mechanisms that can be easily adjusted to increase or decrease the amount of tension based on the weight carried by the elevator. These mechanisms include springs, counterweights, and adjustable rollers, which respond to changes in the load or speed by making slight adjustments to the tension. These adjustments are crucial in maintaining consistent elevator performance. For example, when the elevator car is heavily loaded, the tensioning system automatically adjusts to accommodate the additional weight, ensuring smooth operation. Conversely, when the car is light, the tensioning system reduces the force on the cables, ensuring that excessive tension does not damage the system.

3. Corrosion Resistance and Durability

The materials used in the tension device, including barite, must be resistant to corrosion, particularly because elevator systems often operate in environments with varying levels of humidity or temperature fluctuations. Barite's natural properties make it an ideal choice for use in this application, as it resists degradation from moisture or other environmental factors. This durability ensures that the device continues to function smoothly over an extended period without the need for frequent replacements. Because the tension device is exposed to harsh mechanical stresses, such as constant movement and pressure, materials with superior durability are essential for minimizing maintenance costs and ensuring a long lifespan for the elevator system. The barite elevator tension device is designed with these considerations in mind, ensuring that the system remains effective and reliable for years.

4. Reduced Maintenance Requirements

Elevator systems can be costly to maintain, and minimizing maintenance needs is an important consideration when designing tensioning devices. The barite elevator tension device is engineered for longevity, and its corrosion-resistant properties, coupled with its efficient operation, result in reduced maintenance needs. With fewer breakdowns or wear-and-tear issues, the overall cost of ownership is lowered, making it an attractive option for building owners and managers. A durable tensioning device reduces the frequency of repairs required for other components, such as the ropes, sheaves, and elevator motors. This translates into fewer disruptions to elevator service, which is crucial in buildings with high foot traffic or in commercial spaces where elevator downtime can be costly.

In conclusion, the barite elevator tension device is a critical component of modern elevator systems, ensuring the proper functioning, energy efficiency, and safety of elevators. Its use of barite, with its superior weight, stability, and corrosion resistance, makes it an ideal material for regulating cable tension in traction elevators. By maintaining consistent tension, the device improves ride quality, reduces energy consumption, extends system lifespan, and enhances safety. As the demand for reliable and efficient elevator systems continues to rise, the role of the barite elevator tension device will remain indispensable, ensuring smooth, safe, and cost-effective elevator operations for years to come.

https://www.xizi-ec.com/FTD300C-Tension-device.html

www.xizi-ec.com

Zhejiang Xizi Forvorda Electrical Machinery Co., Ltd.