High-Precision Custom Subframes for the Machinery and Energy Industries

1. Introduction: The Importance of High-Precision Custom Subframes

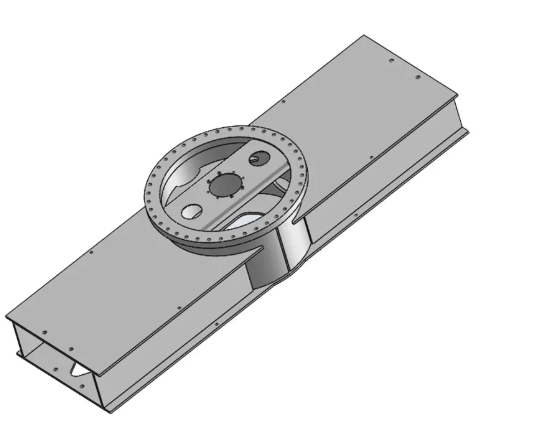

In machinery and energy industries, high-precision custom subframes are fundamental components that ensure the stability and performance of various heavy equipment. At Hengli, we specialize in manufacturing subframes tailored to meet the unique requirements of automotive, construction, agricultural, and energy sectors. With our advanced technology and rich experience, we deliver durable and accurate subframes that enhance equipment reliability and operational efficiency.

2. Hengli’s Expertise in Subframe Manufacturing

Founded in 2002, Hengli has grown into a modern metal processing enterprise with over 1,600 employees and a 300,000 square meter production area. We offer comprehensive services including cutting, bending, welding, machining, and finishing of medium and heavy plates. Our dedicated team collaborates closely with customers to analyze needs and provide customized solutions, ensuring every subframe fits perfectly within the application’s requirements.

3. Cutting-Edge Manufacturing Processes

Our subframe production utilizes state-of-the-art equipment and advanced manufacturing methods:

-

Design & Modeling: Using the latest CAD software, we create detailed 3D models, enabling precise planning and visualization.

-

Material Cutting: With 12 laser cutting machines capable of cutting up to 400mm thick steel, alongside flame and plasma cutters, we ensure precise and efficient raw material processing.

-

Forming & Bending: Our CNC and robotic bending machines offer up to 800 tons of force, achieving complex shapes and tight tolerances.

-

Welding: We employ over 200 certified welders and 40 robotic welding stations, following TUV EN287 and ASME IX certifications to guarantee strength and consistency.

-

Machining & Finishing: CNC machining centers deliver exceptional dimensional accuracy, while surface treatments such as powder coating, painting, and galvanization protect subframes from wear and corrosion.

4. Rigorous Quality Control Ensuring Reliability

At Hengli, quality is paramount. After manufacturing, every subframe undergoes strict inspection procedures, including dimensional checks and strength testing, ensuring compliance with international standards such as ISO 9001:2015. Our factory is audited by Bureau Veritas, reinforcing our commitment to maintaining superior quality and consistency. This thorough quality control results in subframes that perform reliably even in the most demanding industrial environments.

5. Tailored Solutions for Diverse Applications

Our high-precision custom subframes serve a wide range of machinery and energy applications:

-

Construction Machinery: Subframes that provide robust support for heavy equipment used in construction sites.

-

Agricultural Machinery: Components designed to withstand tough agricultural conditions while enhancing machine stability.

-

Special Vehicles & Lifting Equipment: Custom subframes that meet precise specifications to guarantee safety and performance.

-

Energy Sector Equipment: Durable subframes suitable for renewable energy and mining machinery, designed to endure harsh environments.

This flexibility demonstrates our ability to meet diverse industrial demands with customized and reliable subframe solutions.

6. Why Choose Hengli for Your Subframe Needs?

With over two decades of industry experience, Hengli integrates the metal supply chain to provide end-to-end services—from raw material procurement, precision cutting, welding fabrication, CNC machining, to advanced surface treatments. Our capacity to process 120,000 tons of steel annually enables us to serve global clients efficiently with competitive pricing and short lead times. Moreover, our commitment to innovation and integrity builds long-term partnerships with renowned brands across North America, Europe, Asia, and Oceania.

7. Conclusion: Excellence in High-Precision Custom Subframes

Choosing high-precision custom subframes for the machinery and energy industries is a crucial decision impacting the durability and efficiency of your equipment. Hengli’s blend of advanced manufacturing technology, strict quality control, and customer-focused customization positions us as a trusted partner. We invite you to experience our superior products and services that drive your industrial projects toward success.

www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd.