What Is Multi-Layer Bulletproof Glass? Structure, Uses, and Benefits

In an era where personal safety and asset protection are increasingly critical, multi-layer bulletproof glass has emerged as a trusted solution for high-security environments. Whether protecting diplomats, commercial assets, or transportation fleets, this advanced material offers the strength of armor without compromising on clarity.

In this guide, we’ll explore what multi-layer bulletproof glass is made of, how it works, its real-world applications, and how to choose the right type for your needs. We’ll also highlight the innovations brought by Henan Central Glass, a national high-tech enterprise in China renowned for its specialty and ultra-large glass deep processing.

What Is Multi-Layer Bulletproof Glass Made Of?

Multi-layer bulletproof glass—also known as ballistic glass or laminated security glass—is made from alternating layers of:

Tempered or float glass for structural rigidity

Polyvinyl butyral (PVB) or Thermoplastic polyurethane (TPU) as interlayers to absorb energy

Polycarbonate (PC) in high-grade versions to increase impact resistance and flexibility

This structure is bonded under heat and pressure, creating a strong, transparent barrier capable of stopping bullets and resisting blunt force. The best materials for multi-layer bulletproof glass depend on the threat level and application, with polycarbonate being common in higher-security installations.

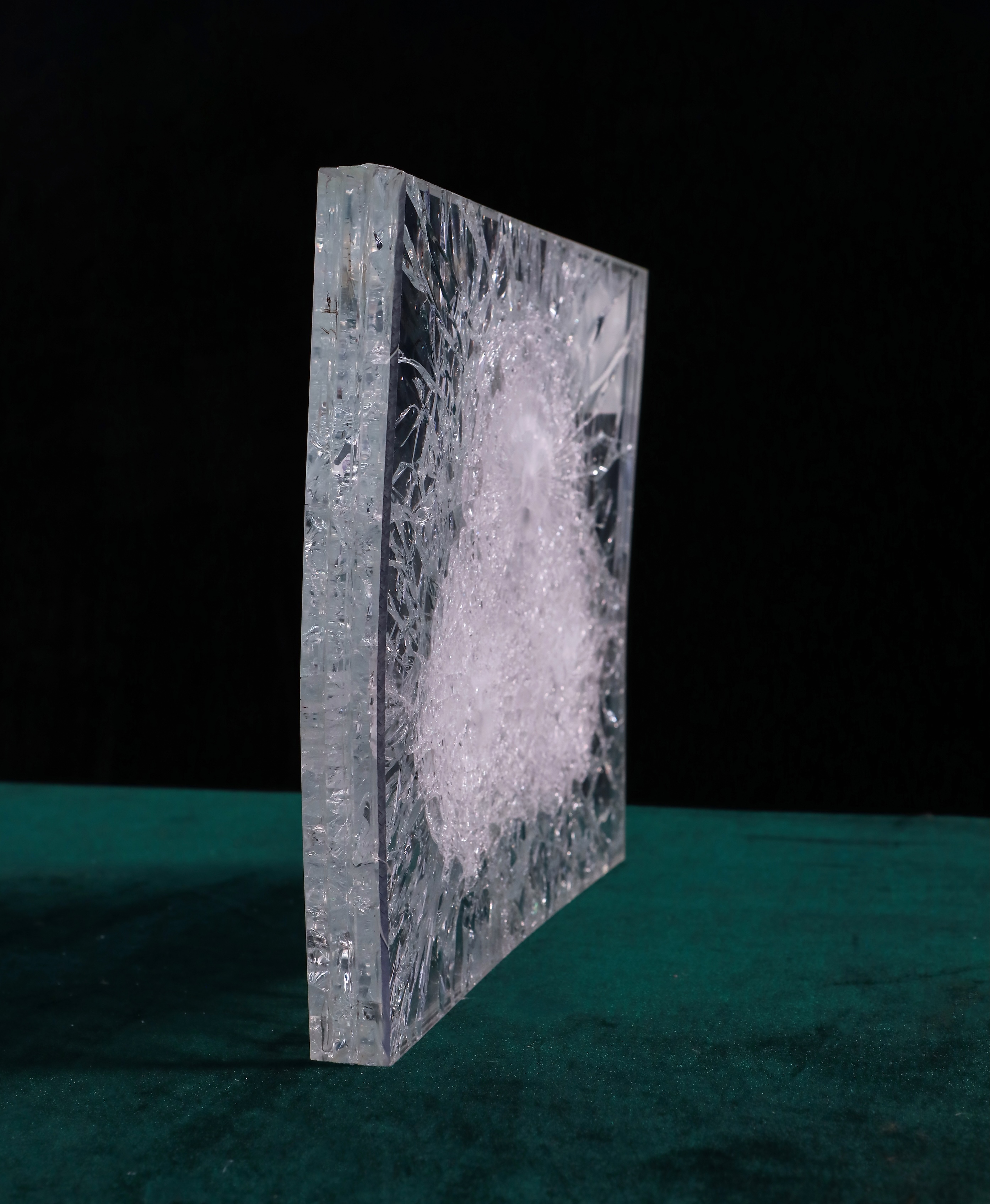

Structure of Multi-Layer Bulletproof Glass

The structure typically includes:

Outer Glass Layer – Often heat-treated for initial impact resistance

Interlayers (PVB/TPU) – Absorb shock and prevent shattering

Inner Glass Layers – Distribute force and add thickness

Optional Polycarbonate Layer – Used for advanced ballistic threats

Anti-spall coating – Prevents glass fragments from flying inward

Henan Central Glass excels in producing custom-layered glass configurations using proprietary lamination and large-format processing technologies, making them one of China’s top bullet proof glass manufacturers.

How Multi-Layer Bulletproof Glass Works

When a bullet hits the glass:

The outer glass layer slows or breaks the bullet

The interlayer absorbs and disperses the energy

The inner layers stop penetration and prevent spalling

Unlike traditional glass, the laminated layers stay intact, holding the bullet and glass fragments in place, protecting people on the other side. This makes it ideal for use in banks, military facilities, armored vehicles, and high-security buildings.

Uses of Bulletproof Glass in Buildings and Vehicles

Multi-layer bulletproof glass is widely used in:

1. Commercial and Government Buildings

Embassies, police stations, military bases

Banks, data centers, corporate offices

Bullet-resistant windows and reception barriers

2. Residential Security

Villas, VIP homes, and safe rooms

Panic room construction and fortified doors

3. Transportation

Armored vehicles, VIP convoys

Cash-in-transit trucks

Trains, airplanes, and naval vessels

4. Infrastructure and Public Spaces

Airports, stadiums, and border checkpoints

Public transport stations and ticketing counters

Henan Central Glass provides customizable glass thickness, shapes, and protection levels to match each unique use case.

Types of Bulletproof Glass and Their Protection Levels

Bulletproof glass is classified based on its ability to stop specific types of ammunition. Some common protection standards include:

NIJ Levels (National Institute of Justice)

Level I: .22 LR

Level II: 9mm

Level IIIA: .44 Magnum

Level III: Rifle rounds (e.g., 7.62mm)

Level IV: Armor-piercing rounds

EN 1063 European Standards (BR Ratings)

BR1 to BR7 for handguns and rifles

SG ratings for shotgun resistance

Choosing the right level depends on the expected threat. Henan Central Glass assists clients by analyzing risks and delivering tailored ballistic glass solutions.

How to Choose the Right Bulletproof Glass for Your Project

When selecting bulletproof glass, consider:

Threat level: Type of firearm or impact risk

Glass thickness: Ranges from 20mm to 100mm or more depending on rating

Weight and installation limits: Especially for doors, vehicles, or elevators

Optical clarity: For transparency and aesthetic needs

Climate resistance: Important for outdoor or harsh environments

Certification: Choose tested and certified products for reliability

Henan Central Glass offers engineering consultation, helping customers across sectors choose the right bulletproof glass with safety, performance, and architectural integration in mind.

How Thick Is Multi-Layer Bulletproof Glass?

The thickness varies with security level:

Standard protection (Level I–IIA): 20–35 mm

Mid-tier (Level III): 40–60 mm

High-risk areas (Level IV or BR7): 70–120 mm

Henan Central Glass has advanced facilities capable of producing extra-large and thick bulletproof glass panels, making them a preferred choice for high-spec international projects.

Top Bullet Proof Glass Manufacturers: Why Henan Central Glass Leads

As a national high-tech enterprise, Henan Central Glass specializes in:

Deep-processing of ultra-large architectural glass

Custom bulletproof glass for vehicles, buildings, and defense

ISO and international ballistic standard certifications

Decades of experience in R&D, design, and large-scale production

State-of-the-art production lines for curved, smart, and hybrid glass types

Their continuous innovation in specialty glass applications has positioned them as one of the leading bulletproof glass manufacturers in China and globally.

Frequently Asked Questions (FAQs)

Q1: What is multi-layer bulletproof glass made of?

It consists of layers of tempered glass, PVB/TPU interlayers, and sometimes polycarbonate.

Q2: How thick is multi-layer bulletproof glass?

Anywhere from 20mm to over 100mm depending on threat level and use case.

Q3: Where is bulletproof glass used?

In government buildings, banks, VIP homes, armored vehicles, and military installations.

Q4: How does bulletproof glass stop bullets?

By absorbing and dispersing kinetic energy through its laminated layers, preventing penetration and reducing spall.

Q5: What is the best material for bulletproof glass?

A combination of tempered glass, polycarbonate, and PVB/TPU interlayers for optimal strength and clarity.

Q6: Can I customize bulletproof glass for my building?

Yes. Henan Central Glass offers bespoke sizes, shapes, and protection levels for specific projects.

Conclusion

Multi-layer bulletproof glass offers a powerful blend of transparency, strength, and peace of mind. Whether protecting critical assets, enhancing military-grade transport, or ensuring the safety of high-profile facilities, it stands as a cornerstone of modern security design.

Henan Central Glass, with its innovation-driven approach and deep manufacturing expertise, is your trusted partner for custom bulletproof glass solutions that don’t compromise on performance, clarity, or design integrity.

Henan Zhongbo Glass helps Guizhou Huajiang Canyon Bridge glass project

Key Characteristics of Bullet-Proof Glass: Strength, Thickness, Transparency

www.hncentralglass.com

Henan Zhongbo Glass Co., Ltd.