Solutions for Efficient Production with Titanium Anode Tanks in Copper Foil Manufacturing

Copper foil plays a crucial role in industries ranging from electronics to energy storage. Its superior conductivity, durability, and adaptability make it indispensable for printed circuit boards, electromagnetic shielding, and particularly lithium-ion batteries. With the growth of renewable energy and electric mobility, demand for high-quality copper foil has increased, driving manufacturers to seek innovations that enhance production efficiency and quality.

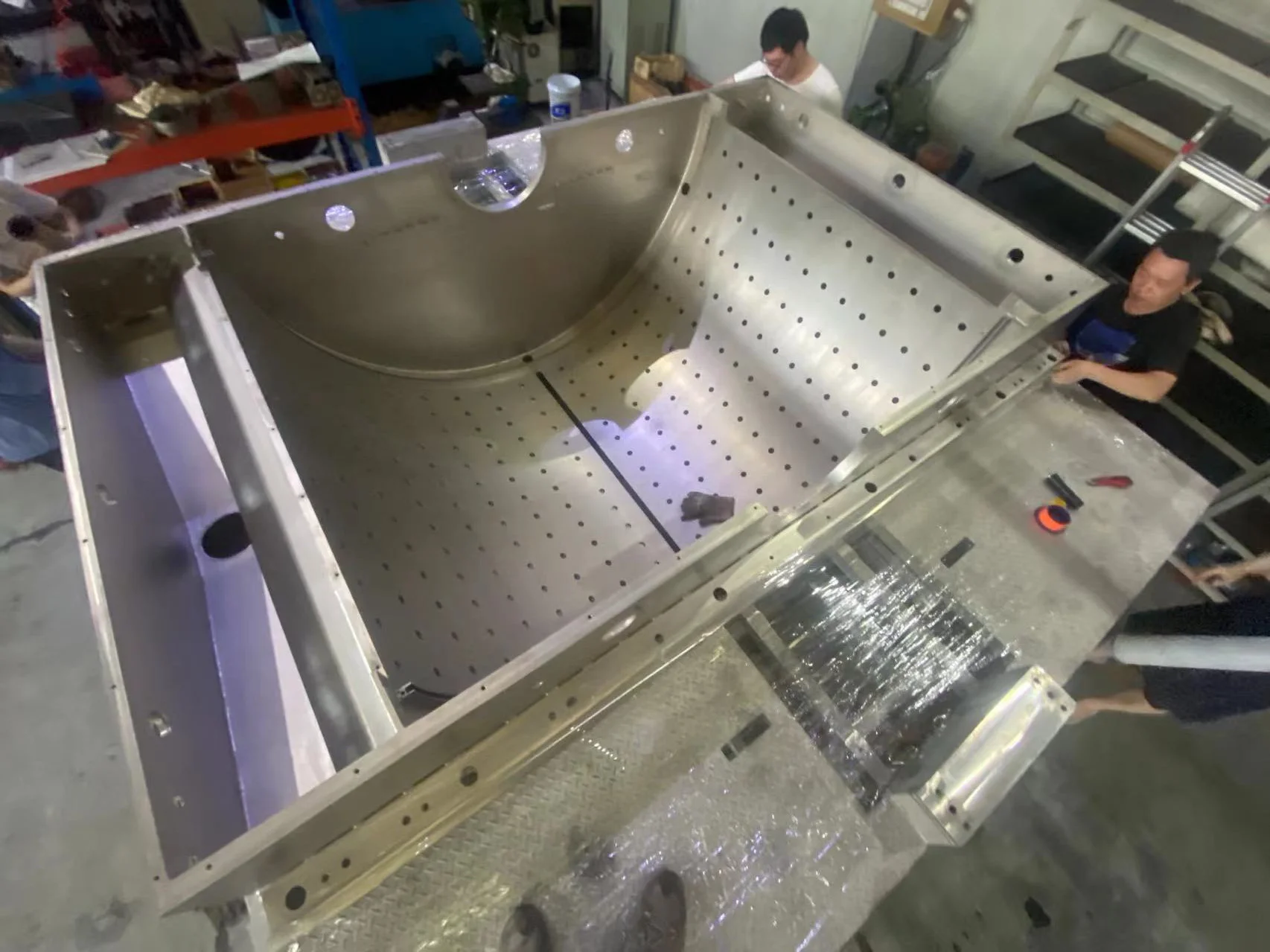

The Importance of Titanium Anode Tanks

Titanium anode tanks are vital in the production process of copper foil, particularly in electroplating and electrolytic refining. Their function is to support uniform copper deposition while resisting corrosion in harsh chemical environments. Unlike conventional materials, titanium combines strength, corrosion resistance, and longevity, making it ideal for continuous industrial use. By integrating titanium anode tanks, manufacturers achieve more reliable operations, reduce downtime, and maintain consistent foil quality.

Advantages of Titanium in Copper Foil Manufacturing

Titanium offers unique advantages over other materials used in anode tanks. Its resistance to acidic electrolytes extends equipment lifespan, reducing the frequency of replacements. Additionally, titanium’s lightweight yet durable structure facilitates easier handling and maintenance. These benefits directly contribute to cost efficiency and operational reliability. For copper foil manufacturers, adopting titanium anode tanks means achieving higher throughput while minimizing production risks.

Enhancing Process Stability and Consistency

In copper foil production, stability and consistency are essential to meet strict industrial standards. Titanium anode tanks provide uniform electrochemical conditions, ensuring that copper deposits evenly across the foil. This eliminates issues such as thickness variations, rough surfaces, or structural weaknesses in the final product. Enhanced process stability also reduces waste, ensuring that resources are utilized efficiently and production lines maintain a steady output.

Contribution to Lithium-Ion Battery Materials

The lithium-ion battery industry relies heavily on copper foil as a current collector. Titanium anode tanks play an important role in producing the high-quality foil required for battery performance. Consistent thickness, smooth surfaces, and defect-free copper layers are crucial for battery safety and efficiency. By enabling superior copper foil quality, titanium anode tanks support the broader energy storage sector, from consumer electronics to electric vehicles.

Timonic’s Dedication to Innovation

Timonic is an enterprise dedicated to the production equipment for new energy lithium battery materials. With a commitment to research, development, and advanced manufacturing, Timonic provides solutions that align with industry demands for quality, efficiency, and sustainability. By integrating titanium anode tanks into its portfolio, the company empowers manufacturers to optimize copper foil production processes. Timonic’s expertise ensures that clients benefit from durable, efficient, and technologically advanced equipment tailored to the energy storage sector.

Improving Operational Efficiency

Efficiency in copper foil manufacturing depends on equipment reliability and optimized workflows. Titanium anode tanks minimize unplanned downtime due to their durability and resistance to corrosion. Their longer lifespan reduces the need for frequent maintenance, allowing production lines to run more continuously. This efficiency directly translates into higher productivity and cost savings, which are essential for competitive manufacturing environments.

Supporting Sustainability Objectives

Sustainability has become a key focus across industries, including copper foil manufacturing. Titanium anode tanks contribute to these goals by reducing material waste and energy consumption. Their extended service life decreases the environmental impact associated with equipment disposal and replacement. Additionally, by enabling more precise and stable copper deposition, titanium tanks reduce the number of defective products, further minimizing waste.

Advancing Safety in Manufacturing Environments

Safety is critical in any industrial production environment. The corrosion resistance of titanium reduces risks of leakage or structural failure in anode tanks, safeguarding both equipment and personnel. Stable electrochemical conditions also ensure safer handling of electrolytes and reduced exposure to hazardous incidents. Manufacturers adopting titanium anode tanks benefit not only from operational advantages but also from enhanced workplace safety.

Expanding Applications in High-Tech Sectors

Beyond copper foil for lithium-ion batteries, titanium anode tanks find applications in producing materials for electronics, aerospace, and other high-tech industries. These sectors require copper foils with exceptional precision and reliability. Titanium’s role in ensuring uniform deposition and consistent quality makes it indispensable for meeting the stringent requirements of advanced technologies.

Integration into Modern Manufacturing Systems

Modern copper foil production facilities increasingly rely on integrated systems that combine automation, data monitoring, and advanced equipment. Titanium anode tanks complement these systems by providing reliable and stable performance. They reduce variability in production, enabling seamless integration with automated quality control and process management tools. This integration helps manufacturers maintain competitiveness in fast-evolving industries.

Reducing Total Cost of Ownership

While titanium anode tanks may represent a higher initial investment compared to conventional alternatives, their long-term cost benefits are substantial. Reduced maintenance, longer service life, and improved efficiency lower the total cost of ownership. Manufacturers save not only on equipment replacement but also on downtime and resource waste. This cost-effectiveness reinforces the value of titanium anode tanks as a strategic investment.

Facilitating Innovation in Product Development

The use of titanium anode tanks allows manufacturers to experiment with new formulations, electrolytes, and copper foil specifications. Their reliability and stability provide a controlled environment for testing innovations in copper foil production. This flexibility supports product development efforts, enabling manufacturers to respond to emerging demands in industries such as energy storage and electronics.

Ensuring Global Competitiveness

The copper foil industry is highly competitive, with global demand driven by the expansion of renewable energy and advanced electronics. Titanium anode tanks enable manufacturers to maintain high-quality standards while optimizing costs and efficiency. By adopting these solutions, companies strengthen their global competitiveness, meeting customer expectations for performance and reliability.

Conclusion

Titanium anode tanks are essential solutions for efficient copper foil manufacturing. Their durability, corrosion resistance, and ability to maintain process stability directly contribute to higher productivity and quality. For industries dependent on copper foil, particularly the lithium-ion battery sector, these tanks support reliable, safe, and sustainable production. Timonic’s dedication to advancing new energy lithium battery material production equipment ensures that manufacturers gain access to innovative solutions tailored to their needs. By adopting titanium anode tanks, the copper foil industry enhances efficiency, safety, and competitiveness in a demanding global landscape.

Why Titanium Anode Tanks Are Essential for Modern Industrial Applications

www.timonic.com.cn

Timonic